Natural Gas Compressor

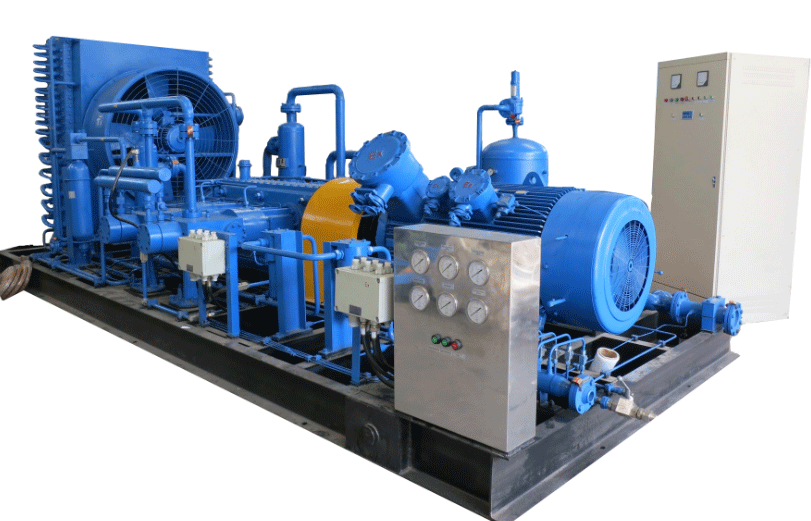

Generalize: M-type and D-type of natural gas compressors are available. The system consists of natural gas compressors, explosion-proof engines, cooling systems, lubricating systems, buffering systems and filtration systems, an oil separator, PLC control system and monitoring system, temperature and pressure sensors, etc.

The cooling system keeps temperature at precise stable level, thus the lubricating system operation is optimized. The system can be modified according to Customer’s request. The system is assembled on a baseplate.

ADEKOM Compressors can realize filling stations(on line, mother and daughter station) with different refuelling strategies.

Designed for suction pressures from 1 to 50 bar abs with a capacity range between 80 and 8000 Nm3/h usually at a final pressure of 251 bar abs (on request up to 351 bar abs). The rated powers are from 40kW up to 600kW.

Besides V-belt driven for the smaller units, direct electric or gas driven compressors with speed/capacity control and bypass function to achieve maximum flexibility and economical operation.

Specifications

Item | Model | Discharge capacity (m³/min) | Speed (r/min) | Suction pressure (Mpa) | Discharge pressure (Mpa) | Motor output (kw) | Dimensions (mm×mm×mm) |

1 | KDW-40/8 | 40 | 740 | 0 | 0.7(0.8) | 250 | 3000×2600×1700 |

2 | KDW-80/2 | 80 | 730 | 0 | 0.2 | 250 | 3000×1100×900 |

3 | KDW-1/0.5-15 | 1 | 730 | 0.05 | 1.5 | 15 | 1870×1700×1350 |

4 | KDW-17/1.5-4.5 | 17 | 730 | 0.15 | 0.45 | 160 | 3700×3100×1790 |

5 | KDW-1/0.02-15 | 1 | 730 | 0.002 | 1.5 | 11 | 1870×826×1300 |

6 | KDW-1/2-16 | 1 | 730 | 0.2 | 1.6 | 11 | 2000×1700×1100 |

7 | KDW-1/5-20 | 1 | 730 | 0.5 | 2 | 18.5 | 2000×1775×1300 |

8 | KDW-1/0.02-25 | 1 | 730 | 0.002 | 2.5 | 15 | 1870×1700×1050 |

9 | KDW-0.3/20-50 | 0.3 | 730 | 2 | 5 | 22 | 1650×2400×930 |

10 | KDW-1.65/4-22.5 | 1.65 | 730 | 0.4 | 2.25 | 22 | 1700×2040×1200 |

11 | KDW-2.8/(3~5)-28 | 2.8 | 740 | 0.3~0.5 | 2.8 | 90 | 4400×2500×2100 |

12 | KDW-35/1-6 | 35 | 740 | 0.1 | 0.6 | 280 | 4400×2500×2100 |

13 | KDW-12.78/4-31.8 | 12.7 | 485 | 0.4 | 3.18 | 355 | 7200×5500×3000 |

14 | KD-0.08/250-500 | 0.08 | 1000 | 25 | 50 | 135 | 6000×2300×2550 |

15 | KDWWJD-3/(0~0.2)-7 | 3 | 740 | 0~0.02 | 0.7 | 30 | 5000×2300×2400 |

16 | KDW-13/4.7-26 | 13 | 485 | 0.47 | 2.6 | 315 | 6200×5270×2825 |

17 | KDW-37/4-9 | 37 | 485 | 0.4 | 0.9 | 355 | 6200×7745×3150 |

18 | KD-4.2/(3~6)-250 | 4.2 | 740 | 0.3~0.6 | 25 | 375 | 6000×4700×2950 |

19 | KD-2.4/(16~23)-210 | 2.4 | 740 | 1.6~2.3 | 21 | 355 | 5000×3500×2500 |

20 | KD-2.5/(12~14)-250 | 2.5 | 740 | 1.2~1.4 | 25 | 250 | 5000×3500×2000 |

21 | KDF-1.12/17-250 | 1.12 | 740 | 1.7 | 25 | 160 | 4000×3500×2900 |

22 | KDW-5/(0.05~0.1)-15 | 5 | 740 | 0.005~0.01 | 1.5 | 55 | 3716×2334×1495 |

23 | KDF-1.4/(16~20)-250 | 1.4 | 585 | 1.6~2 | 25 | 200 | 4000×3500×2910 |

24 | KDF-3.5/(7~10)-250 | 3.5 | 740 | 0.7~1 | 25 | 550 | 6600×4300×2500 |

25 | KD-1.7/(35~40)-210 | 1.7 | 740 | 3.5~4 | 21 | 355 | 5500×4200×1900 |

26 | KDF-0.32/35~250 | 0.32 | 740 | 3.5 | 25 | 75 | 2500×2500×2300 |

27 | KD-1.65/(25~35)-210 | 1.65 | 740 | 2.5~3.5 | 21 | 355 | 6500×4300×1900 |

28 | KD-12.5/0.05-5 | 12.5 | 740 | 0.005 | 0.5 | 75 | 4300×2590×1700 |

29 | KDW-2.5/3-12 | 2.5 | 740 | 0.3 | 1.2 | 37 | 4000×2300×1900 |

30 | KDF-2.5/(12~14)-250 | 2.5 | 740 | 1.2~1.4 | 25 | 37 | 5000×4300×1800 |

31 | KDF-2.8/(8~16)-250 | 2.8 | 740 | 0.8~1.6 | 25 | 355 | 5500×4300×1800 |

32 | KD-1/(25~35)-250 | 1 | 740 | 2.5~3.5 | 25 | 200 | 5500×3300×1600 |

33 | KD-1.3/(60~85)-250 | 1.3 | 740 | 6~8.5 | 25 | 355 | 6500×4300×1900 |

34 | KDW-9/0.01-14 | 9 | 740 | 0.001 | 1.4 | 90 | 5500×2750×2250 |

35 | KDW-10(0~0.1)-7 | 10 | 980 | 0~0.01 | 0.7 | 75 | 4000×2500×2100 |

36 | KDW-16/17 | 16 | 980 | 0 | 1.7 | 160 | 4620×2640×1620 |

37 | KDW-1.1/50-84 | 1.1 | 980 | 5 | 8.4 | 90 | 4305×3000×1534 |

38 | KDW-11/0.1-8.5 | 11 | 740 | 0.01 | 0.85 | 90 | 5600×2850×2000 |

39 | KDW-13.4/0.3-20 | 13.4 | 740 | 0.03 | 2 | 160 | 3780×3235×2220 |

40 | KDW-18/0.15-4.5 | 18 | 980 | 0.015 | 0.45 | 110 | 4970×2670×1866 |

41 | KDW-4.5/12 | 4.5 | 740 | 0 | 1.2 | 45 | 3340×2700×1980 |

42 | KDF-1/(28.5~30)-250 | 1 | 740 | 2.85~3.0 | 25 | 200 | 6600×3500×2500 |

43 | KDW-17/0.5-15 | 17 | 990 | 0.05 | 1.5 | 185 | 5370×3100×2300 |

44 | KDW-8/(26~30.5)-(29.5~35) | 8 | 740 | 2.6~3.05 | 2.95~3.5 | 160 | 4000×2590×2200 |

45 | KD-3.45/(2.8~8.2)-250 | 3.45 | 740 | 0.28~0.82 | 25 | 200 | 4200×3900×2300 |

46 | KD-1.95/(5.8~12.2)-250 | 1.95 | 740 | 0.58~1.22 | 25 | 185 | 4200×3900×2300 |

47 | KDW-5.2/1.7-10 | 5.2 | 740 | 0.17 | 1 | 75 | 4650×2660×1700 |

48 | KDWWJD-5/(0~0.2)-7 | 5 | 740 | 0~0.02 | 0.7 | 37 | 5000×2300×2400 |

49 | KDF-4.2(3~6)-250 | 4.2 | 740 | 0.3~0.6 | 25 | 280 | 5500×4500×1800 |

50 | KDF-1.45/(20~35)-250 | 1.45 | 740 | 2-3.5 | 25 | 280 | 5500×4500×1800 |

51 | KD-4.4/(0.8~3.2)-250 | 4.4 | 740 | 0.08~0.32 | 25 | 185 | 4200×3900×2300 |

Item | Model | Discharge capacity (m³/min) | Suction pressure (Mpa) | Discharge pressure (Mpa) | Motor output | Weight (T) | Dimensions (mm×mm×mm) |

1 | KM-2.4/12-160 | 2.4 | 1.2 | 16 | 315KW | ≈10 | 5800×3100×1600 |

2 | KM-1.7/30-250 | 1.7 | 3 | 25 | 355KW | ≈12 | 5800×3000×2000 |

3 | KM-1.4/30-250 | 1.4 | 3 | 25 | 280KW | ≈12 | 5800×3000×2000 |

4 | KM-1.1/60-250 | 1.1 | 6 | 25 | 280KW | ≈12 | 5800×3000×2000 |

5 | KM-8.4/5-40 | 8.4 | 0.5 | 4 | 280KW | ≈8 | 5800×2500×1600 |

6 | KM-3/24-80 | 3 | 2.4 | 6 | 281KW | ≈8 | 5800×2500×1600 |

Natural Gas Compressor Application

Gas-filling stations

Customer Case

LINK

LINK